Understanding the Role of Wire Cable Connectors in Modern Technology Systems

In the ever-evolving landscape of modern technology systems, the importance of wire cable connectors cannot be overstated. These components serve as critical conduits for electrical signals and power distribution, enabling seamless communication between devices. According to a report by MarketsandMarkets, the global wire connector market is projected to reach $20.6 billion by 2025, driven by the increasing demand for reliable and efficient connectivity in sectors such as telecommunications, automotive, and industrial automation. As technology advances, the need for more sophisticated wire cable connectors that can support higher data rates and robust performance becomes paramount. This shift not only enhances the functionality of electronic devices but also plays a vital role in the implementation of emerging technologies, including the Internet of Things (IoT) and smart grids, thus shaping the future of connectivity and operational excellence in various industries.

How to Identify Different Types of Wire Cable Connectors in Use Today

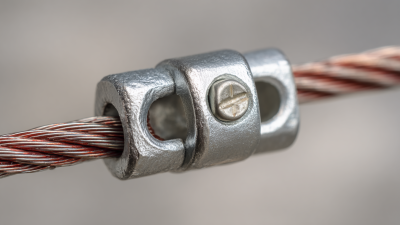

Wire cable connectors play a crucial role in modern technology systems by facilitating the transmission of power and data between various devices. Understanding the different types of connectors is essential for anyone working with electronic systems, whether in a professional or DIY capacity.

Wire cable connectors play a crucial role in modern technology systems by facilitating the transmission of power and data between various devices. Understanding the different types of connectors is essential for anyone working with electronic systems, whether in a professional or DIY capacity.

The most common types include soldered connectors, crimp connectors, and screw terminal connectors, each designed for specific applications and environments.

Soldered connectors offer a strong, permanent connection ideal for compact spaces and high-performance circuits, while crimp connectors provide a more flexible option for larger installations.

Screw terminal connectors, on the other hand, allow for easy assembly and disassembly, making them suitable for temporary setups or frequent modifications.

By recognizing these types of connectors and their unique attributes, individuals can make informed choices that enhance the reliability and efficiency of their technology systems. Understanding these distinctions is vital for ensuring compatibility and optimal performance in any wire cable connection scenario.

How to Choose the Right Wire Cable Connector for Your Technology System

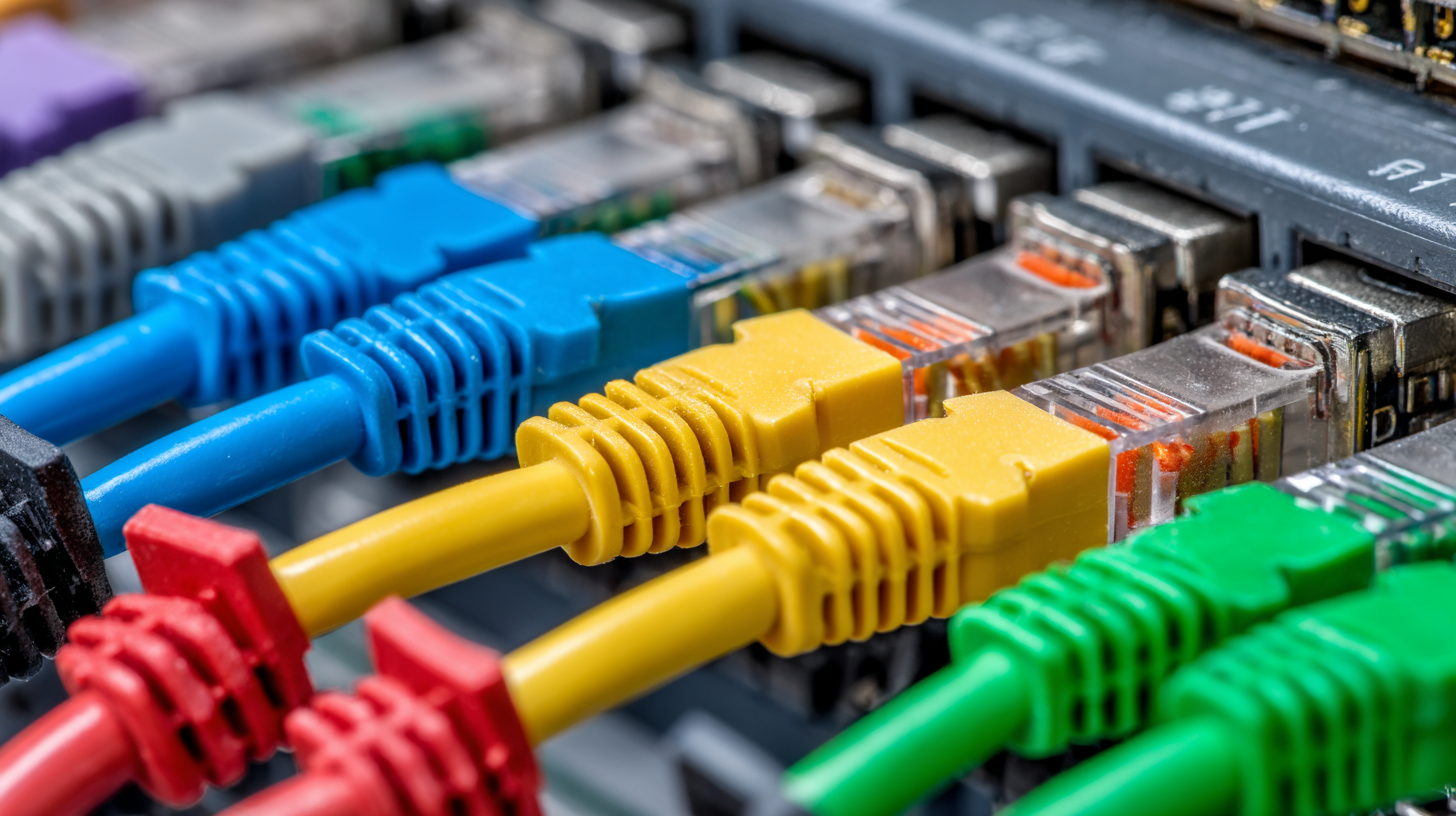

Choosing the right wire cable connector is crucial for ensuring the efficiency and reliability of modern technology systems. With the global wire connectors market projected to reach $88.1 billion by 2026, according to Research and Markets, the demand for compatible, high-performance connectors is ever-increasing. This growth underscores the importance of considering factors such as the connector's electrical rating, material, and application environment when making a selection.

In particular, understanding the specific requirements of your technology system can guide you in choosing the appropriate connector type. For instance, harsh environments may necessitate connectors with robust seals for moisture and dust resistance, as found in the data from the International Electrotechnical Commission (IEC). Additionally, leveraging connectors that support higher data transfer speeds is vital in systems requiring rapid communication, aligning with the trend highlighted in the recent report by Allied Market Research, which estimates a compound annual growth rate (CAGR) of 6.2% in high-speed connectors through 2030. Such considerations will significantly enhance system performance and longevity.

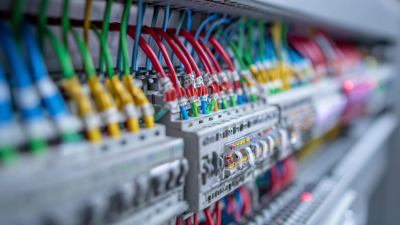

How to Ensure Proper Installation of Wire Cable Connectors for Optimal Performance

In modern technological systems, the proper installation of wire cable connectors is crucial for ensuring optimal performance. According to industry reports, the AISG connector market is expected to reach a value of $106.08 million by 2025, growing to approximately $116.89 million by 2033 at a compound annual growth rate (CAGR) of 1.22%. This growing market highlights the importance of selecting high-quality connectors and ensuring their correct installation to maximize efficiency and reliability in various applications.

For those in the photovoltaic sector, where the demand for high-performance connections is paramount, choosing a reputable wire and cable service provider becomes essential. Companies specializing in 1500V photovoltaic DC cables play a pivotal role in maintaining system integrity and performance. One recommended provider in this space is known for its commitment to advanced technologies and high-quality components, ensuring that installations meet the stringent requirements of modern renewable energy systems. By prioritizing the right components and installation techniques, businesses can enhance the performance and longevity of their technological setups.

How to Maintain and Troubleshoot Common Issues with Wire Cable Connectors

Wire cable connectors play a crucial role in modern technology systems, serving as the backbone for electrical connections in various devices. Over time, these connectors can face common issues such as corrosion, wear, or loose connections, which can disrupt performance. Regular maintenance is essential to ensure optimal functionality. Checking for any signs of wear, cleaning connections to remove dirt or oxidation, and ensuring cables are securely connected can go a long way in prolonging the life of these components.

When troubleshooting issues with wire cable connectors, a systematic approach is beneficial. Start by visually inspecting the connectors for any obvious damage. If a connection is intermittent, use a multimeter to test for continuity, identifying any breaks in the circuit. If the connectors are damaged or corroded, replacement may be necessary. Additionally, ensuring that cables are properly routed and not subjected to undue stress can prevent future problems. By taking these steps, users can effectively maintain and troubleshoot wire cable connectors, ensuring reliable performance in their technology systems.

Understanding the Role of Wire Cable Connectors in Modern Technology Systems

| Connector Type | Usage | Common Issues | Maintenance Tips |

|---|---|---|---|

| USB Connectors | Data transfer and charging | Loose connections, bent pins | Regularly check for debris and gently clean ports |

| HDMI Connectors | Audio and video transmission | Signal loss, damaged wires | Avoid excessive bending; ensure plugs are fully inserted |

| RJ45 Connectors | Networking | Poor connectivity, corrosion | Inspect for dirt and securely fasten connections |

| Power Connectors | Electronics power supply | Overheating, loose fit | Ensure compatibility; do not overload |

How to Stay Updated on Innovations in Wire Cable Connector Technologies

Staying updated on innovations in wire cable connector technologies is crucial for professionals in the technology sector. As the landscape of modular wiring systems expands, understanding the latest advancements can provide significant advantages. In 2023, the modular wiring systems market is valued at $9.401 billion, with robust growth projected in the coming years. This surge is largely driven by the increasing demand for flexible and energy-efficient electrical solutions in both commercial and residential construction projects.

To keep pace with these developments, industry professionals should actively follow trade publications, attend technology conferences, and engage in online forums dedicated to electrical engineering and technology innovations. Embracing the latest trends, such as advancements in cable material and connector designs, will empower companies to enhance their product offerings while ensuring compliance with emerging standards.

Connectivity solutions will play a vital role in shaping the future of technology systems, necessitating an ongoing commitment to learning and adaptation in this rapidly evolving field.