The Ultimate Guide to Understanding Control Wires: Applications, Types, and Best Practices

Control wires are an integral component in the automation and control systems that underpin modern industrial and residential applications. According to a report by MarketsandMarkets, the global automation market is expected to reach $214 billion by 2025, highlighting the increasing reliance on sophisticated control systems that utilize control wires for effective operation. These wires facilitate the communication between various components in electrical systems, ensuring precise and reliable control over machinery, lighting, and HVAC systems. As the demand for energy-efficient and smart solutions continues to grow, understanding the types, applications, and best practices surrounding control wires becomes crucial. This guide aims to provide insights into these essential elements, equipping professionals and enthusiasts alike with the knowledge necessary to optimize their use of control wires in various contexts.

Understanding Control Wire Basics: Definitions and Key Features

Control wires play a crucial role in the seamless operation of various electrical systems, from industrial machinery to building automation. Understanding the basic definitions and key features of control wires is essential for professionals in the field. Control wires are typically low-voltage, multi-conductor cables that transmit signals between control devices, such as relays, sensors, and actuators. According to a report by the National Electrical Manufacturers Association (NEMA), the market for control wiring in industrial applications is expected to grow at a CAGR of 5.7% over the next five years, indicating an increasing reliance on these essential components.

Control wires play a crucial role in the seamless operation of various electrical systems, from industrial machinery to building automation. Understanding the basic definitions and key features of control wires is essential for professionals in the field. Control wires are typically low-voltage, multi-conductor cables that transmit signals between control devices, such as relays, sensors, and actuators. According to a report by the National Electrical Manufacturers Association (NEMA), the market for control wiring in industrial applications is expected to grow at a CAGR of 5.7% over the next five years, indicating an increasing reliance on these essential components.

When selecting control wires, it’s important to consider their insulation type, conductor resistance, and temperature rating. High-quality insulation materials like PVC, Teflon, and polyethylene can greatly enhance durability and performance. Additionally, the choice of wire gauge impacts the efficiency of signal transmission; for instance, thinner wires can lead to increased resistive losses.

Tips: Always adhere to local electrical codes and standards when installing control wires. Utilize color coding to simplify maintenance and troubleshooting. Regularly inspect connections and wire integrity to prevent unexpected system failures.

Exploring Different Types of Control Wires and Their Specific Uses

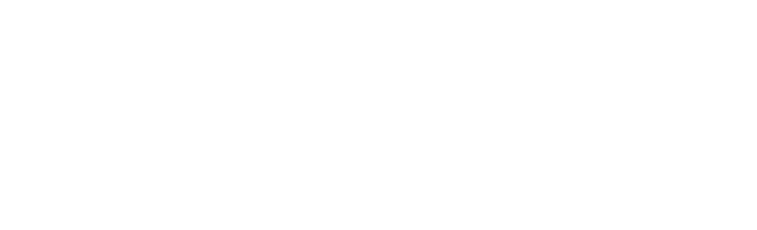

Control wires are vital in various applications, serving as the backbone for communication and function within electrical systems. Among the different types of control wires, low-voltage wires, such as those used in security and alarm systems, are essential for transmitting signals over short distances. Their resilience and ability to operate in diverse environments make them perfect for outdoor applications or where exposure to the elements is a concern.

Another significant category includes twisted pair wires, commonly utilized in data transmission and networking. They minimize electromagnetic interference, ensuring a stable and reliable connection. Additionally, shielded control cables provide extra protection against external noise, making them suitable for industrial settings where heavy machinery may cause interference. Understanding the specific uses and applications of these control wire types can significantly enhance system performance and reliability, ensuring that various components communicate effectively while maintaining operational integrity.

The Ultimate Guide to Understanding Control Wires

This chart illustrates the various applications of control wires in different industries.

Best Practices for Installing Control Wires Safely and Effectively

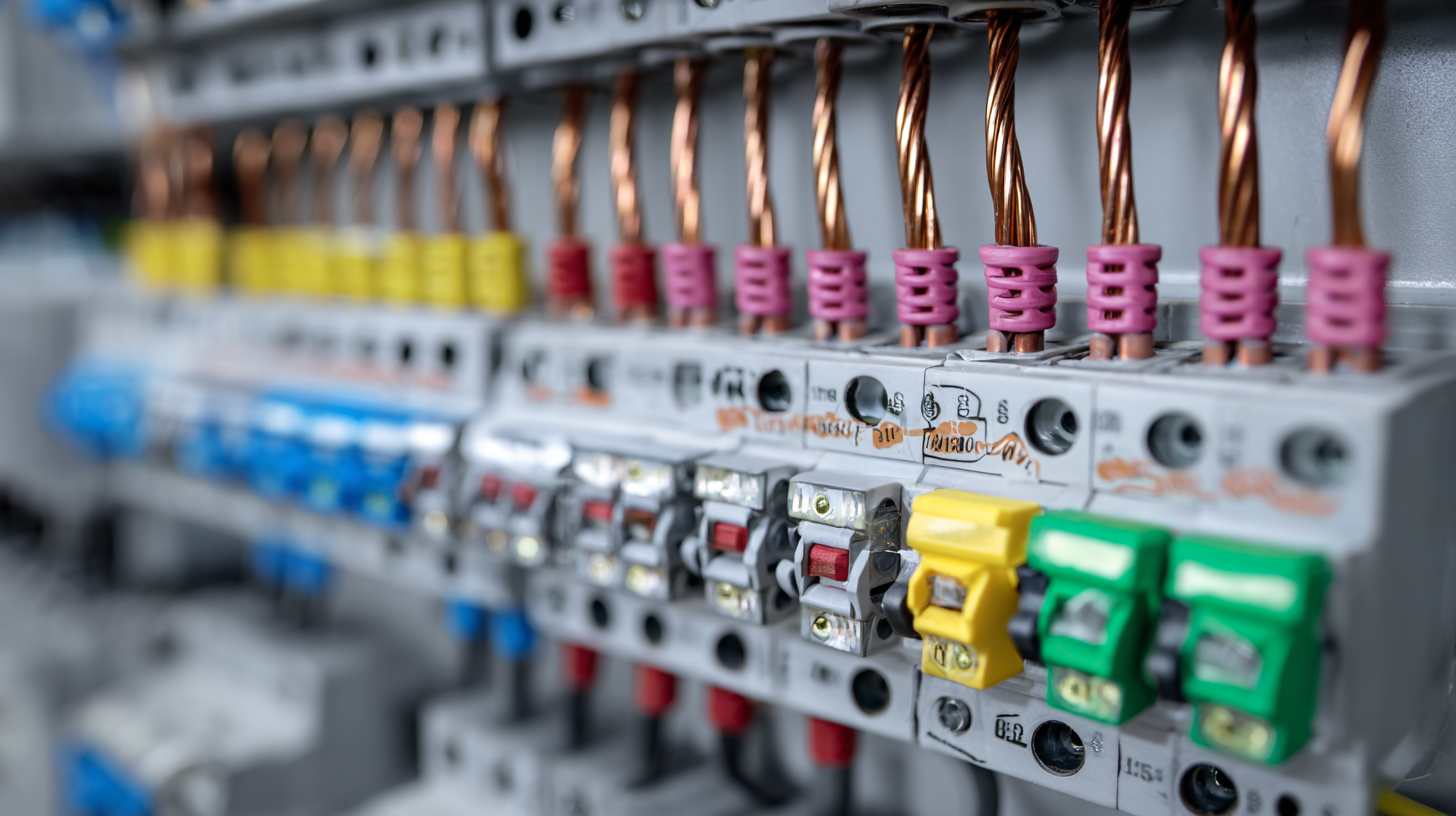

Installing control wires safely and effectively is crucial for ensuring the proper functioning of electrical systems. One of the best practices is to follow local electrical codes and standards, which provide guidelines for wiring methods, materials, and installation techniques. It's essential to use appropriate wire types that suit the specific electrical load and environmental conditions. This includes selecting wires with the right gauge to prevent overheating and utilizing insulated wire to mitigate short-circuit risks.

Another important aspect is to maintain proper routing of control wires. Avoid routing wires through areas with high voltage lines or magnetic interference, as this can degrade the performance and reliability of the control systems. Organizing wires within conduit or raceways not only protects them from physical damage but also simplifies future maintenance.

Additionally, employing color codes and clear labeling can aid in troubleshooting and help electricians quickly identify circuits during inspections or repairs. Implementing these practices ensures a safer installation and enhances the longevity and efficiency of the control wiring system.

Troubleshooting Common Issues with Control Wire Applications

When working with control wires, troubleshooting common issues can be a significant challenge. One of the primary problems involves poor connectivity, which is often caused by frayed wires or loose connections. Regular inspections can help identify areas where wear and tear may have occurred, allowing for timely repairs. Additionally, utilizing high-quality connectors can reduce the risk of connectivity issues, ensuring a more reliable control system.

Another common issue is signal interference, which can disrupt the intended operations of control wires. This often occurs in environments with high electromagnetic interference (EMI), such as factories with heavy machinery. To mitigate this, it's advisable to route control wires away from high-EMI sources and consider using shielded cables. Furthermore, implementing proper grounding techniques can significantly reduce interference and enhance overall system performance. Regularly reviewing the installation and maintenance practices for control wires can help identify potential problems before they escalate, ensuring smooth operations.

The Ultimate Guide to Understanding Control Wires: Applications, Types, and Best Practices - Troubleshooting Common Issues with Control Wire Applications

| Control Wire Type | Applications | Common Problems | Troubleshooting Tips |

|---|---|---|---|

| Low Voltage Control Wire | Lighting Control, HVAC Systems | Intermittent Connections | Check for loose connections and corrosion. |

| Shielded Control Wire | Signal Transmission, Industrial Applications | Signal Interference | Use good grounding practices and verify shielding continuity. |

| Multi-Conductor Control Wire | Complex Control Circuits | Crossed Wires | Label each conductor and verify connections before powering on. |

| Thermostat Wire | Temperature Control, HVAC Systems | Thermostat Not Responding | Check for power supply and ensure the wire is correctly connected. |

| Control Cable | Motor Control, Automation | Cable Breakage | Inspect cable routing for sharp bends and check for physical damage. |

Future Trends in Control Wire Technology and Innovations

As technology continues to evolve, the control wire industry is witnessing significant innovations that are shaping its future. One of the most notable trends is the increasing integration of smart technology, allowing for more efficient and automated control systems. Advancements in IoT (Internet of Things) connectivity enable control wires to communicate seamlessly with various devices, providing real-time monitoring and control capabilities. This not only enhances functionality but also improves safety and reliability in applications ranging from industrial automation to smart homes.

Tips: When selecting control wires for your system, prioritize options that support IoT connectivity to future-proof your installation. Look for wires with enhanced insulation and durability, as these features will ensure longevity and minimize maintenance costs.

Another emerging trend is the emphasis on sustainability. Manufacturers are now focusing on eco-friendly materials and practices, reducing the environmental impact of control wire production. Innovations like biodegradable sheathing and recyclable components are gaining popularity. These changes not only meet regulatory requirements but also cater to the growing consumer demand for sustainable products.

Tips: Consider incorporating control wires made from sustainable materials in your projects to align with environmental goals and appeal to eco-conscious clients. Always explore suppliers who are committed to sustainability in their production processes for the best options.