Top 10 Cable Fittings You Need to Know About?

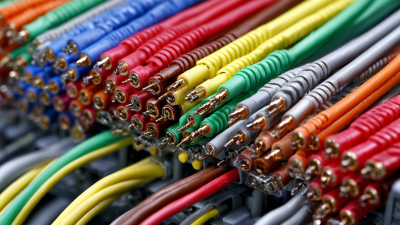

When working on electrical projects, understanding cable fittings is crucial. These components play a vital role in ensuring safety and functionality. The right fittings guarantee secure connections and protect against environmental factors.

Choosing the appropriate cable fittings can be overwhelming. There are many options available, each suited for different needs. Some fittings may seem ideal but fail in real-world applications. It’s essential to assess their durability and compatibility.

Neglecting the right fittings can lead to serious issues. Poor connections may cause power failures or hazards. By knowing the top 10 cable fittings, you can make informed decisions. These insights will help you avoid common pitfalls. With careful selection, your projects can achieve both efficiency and safety. Understanding cable fittings is an investment in quality work.

Understanding Cable Fittings: Definition and Importance

Cable fittings play a crucial role in electrical systems. They secure cables, provide strain relief, and ensure safety. According to recent industry reports, over 30% of electrical failures stem from improper cable connections. This highlights the importance of selecting the right fittings.

Understanding cable fittings starts with recognizing their types and purposes. They include connectors, clamps, and grommets. Each type serves a unique role in the overall integrity of electrical installations. Proper selection and installation can reduce risks significantly. In fact, up to 25% of maintenance costs in electrical setups are due to faulty fittings.

Tips: Always assess the environment where cables will be installed. Factors like temperature and humidity affect cable performance. Ensure fittings match the cable type for optimal function. Regular inspections are vital, as wear can lead to failures. In situations where connections seem loose, re-evaluating your choice can save time and money. Don't overlook the need for quality — cheap fittings can have hidden costs.

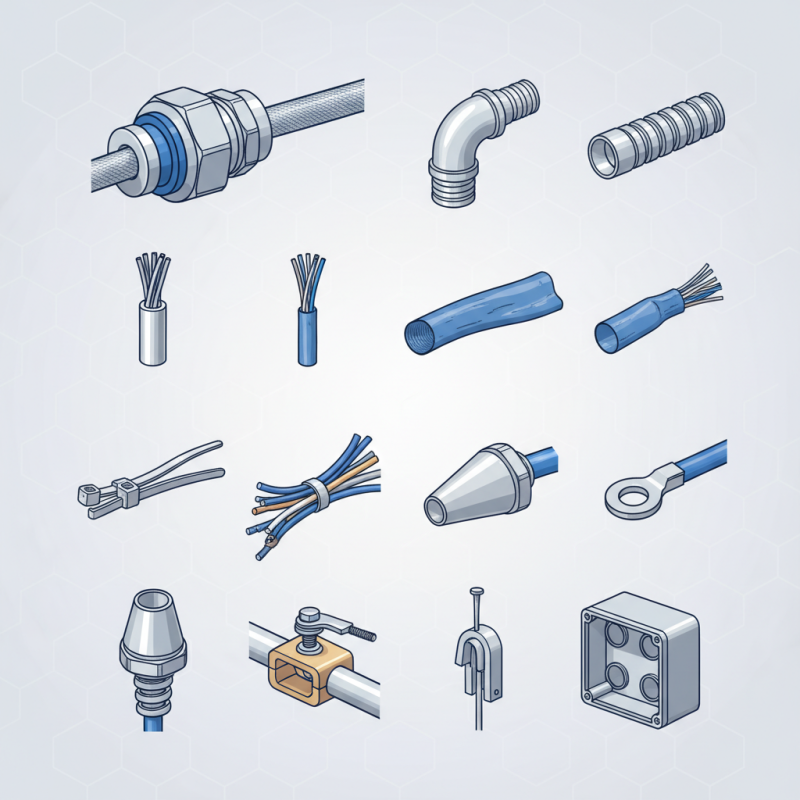

Types of Cable Fittings: An Overview of Common Options

Cable fittings play a crucial role in electrical systems. They ensure secure connections and proper protection for cables. Common types include connectors, adapters, and junction boxes. According to industry reports, nearly 45% of electrical failures can be traced back to improper fittings. This highlights the significance of choosing the right type.

Connectors are fundamental in any wiring project. They come in various sizes and materials. Each type serves a specific purpose. For instance, some connectors are designed for high-voltage applications, while others are suitable for low-voltage systems. This variety can be overwhelming. Understanding the specifications is vital to avoid mishaps.

Junction boxes are another essential fitting. They house wire connections and protect against environmental factors. Data indicates that poorly sealed junction boxes can increase maintenance costs by up to 30%. It's easy to overlook these details, but consequences can be significant. Selecting appropriate fittings requires careful consideration of the project's needs and environment. Flexibility in choice is key, but clarity in purpose is essential.

Key Features to Consider When Choosing Cable Fittings

When choosing cable fittings, several key features demand attention. The size and type of fitting are crucial. Ensure that the fitting matches the cables involved. A loose connection can lead to inefficiencies or potential hazards. Sometimes, measurements can be off. Double-checking can save you trouble later.

Material is another vital consideration. Some fittings are made of plastic, while others use metal. Metal fittings tend to offer greater durability. Yet, they may come with a higher cost. Weigh the pros and cons of each material. Look for corrosion resistance if you’re in a moist environment. It’s easy to overlook this aspect, but it can significantly impact performance.

The ease of installation is worth pondering too. Some fittings require special tools or skills. If you’re a novice, opt for simpler options. Complicated installations can lead to mistakes. Lastly, pay attention to the weight capacity. Each fitting has its limits. Using them beyond their capacity can lead to failure. Understand these limits thoroughly for your project’s safety.

Top 10 Cable Fittings You Need to Know About

| Fitting Type | Material | Application | Key Feature | Temperature Range |

|---|---|---|---|---|

| Cable Gland | Brass | Industrial | Sealing and strain relief | -20°C to +100°C |

| Connector | Polymer | Telecommunications | Easy assembly | -40°C to +85°C |

| Cable Tray | Steel | Electrical systems | Support for vertical and horizontal cabling | -10°C to +70°C |

| Heat Shrink Tube | Polyolefin | Automotive | Insulation and protection | -55°C to +125°C |

| Wire Nuts | Plastic | Residential | Secure wire connections | -20°C to +75°C |

| Terminal Block | Nylon | Industrial | Organized wiring | -30°C to +85°C |

| Adhesive Lined Heat Shrink | Polyolefin | Marine | Waterproof seal | -40°C to +125°C |

| Cable Tie | Nylon | General use | Easy bundling | -40°C to +85°C |

| Split Loom Tubing | Polyethylene | Automotive | Cable protection | -40°C to +90°C |

| Cable Clamp | Steel | Electrical installations | Secure fastening | -20°C to +70°C |

Installation Guidelines for Different Cable Fitting Types

When it comes to cable fittings, proper installation is crucial for safety and performance. Each type has unique requirements. For instance, a report by the Electrical Contractors Association emphasizes that improper installation can lead to a 20% increase in system failures. This statistic highlights the importance of adherence to guidelines.

In installations, the choice of fittings significantly impacts the functioning of electrical systems. For rigid conduit, secure connections are vital. Incorrectly tightened fittings can cause friction, leading to overheating. Conversely, flexible conduit fittings require careful alignment. Misalignment can result in unnecessary strain on cables, diminishing their lifespan. According to industry research, about 15% of electrical fires are linked to poor fitting installations.

It's important to inspect cable features before installation. Some cables are susceptible to environmental factors. If improperly fitted, moisture ingress can occur, severely affecting performance. Additionally, not all fittings are compatible with all cable types. When in doubt, consult updated guidelines. Each choice matters significantly. A single oversight can lead to costly repairs down the line.

Safety Standards and Regulations for Cable Fittings

When it comes to cable fittings, safety is paramount. Proper adherence to safety standards can prevent accidents and ensure longevity. According to the National Electrical Manufacturers Association (NEMA), around 30% of electrical failures are linked to improper fittings. Understanding these standards helps mitigate risk.

Tip: Always consult the latest safety codes relevant to your project. The National Fire Protection Association (NFPA) provides guidelines that every installer should check. For instance, connectors must meet specific ratings for different environments, like wet or corrosive conditions.

It's easy to overlook these details, but ignoring them can lead to failures. Not all installations are straightforward. Some might require extra attention to detail. Ensuring that fittings match the rated capacity is crucial. A mismatch can result in overheating and potential hazards.

Tip: Regular inspections can catch issues early. The International Electrotechnical Commission (IEC) suggests routine checks at least once a year. This practice can identify wear and tear before they become significant problems. Taking safety seriously today can save trouble tomorrow.

Top 10 Cable Fittings and Their Compliance with Safety Standards

This chart illustrates the compliance levels of different cable fittings with established safety standards and regulations. Each fitting is evaluated based on its adherence to global safety guidelines, represented as a percentage for clarity.

Related Posts

-

How to Choose the Right Wire Clamp for Your Projects: A Complete Guide

-

Top 10 Cable Ends You Need to Know for Better Connections and Performance

-

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

-

Top 10 Cable Connectors You Need for Your Electronics Projects

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

2025 Top Cable Harness Innovations and Trends You Need to Know