Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

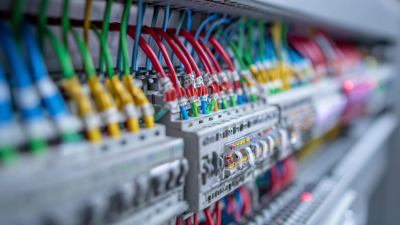

In the ever-evolving world of electrical projects, selecting the right materials is crucial for ensuring efficiency, safety, and longevity. Among these materials, power wire plays a pivotal role, serving as the backbone for electrical connections and system integrity. With advancements in technology and increasing demands for energy-efficient solutions, understanding the various types of power wire available in 2023 is more important than ever.

In this article, we will explore the top 10 power wire types that every electrician and DIY enthusiast should consider for their upcoming projects. From traditional copper wires to innovative solutions like aluminum and fiber optic cables, each type has unique properties and applications that cater to different needs. Whether you are working on residential wiring, commercial installations, or specialized industrial applications, being informed about the best options available will not only enhance the performance of your projects but also ensure compliance with safety standards. Join us as we delve into the essential power wire types that can elevate your electrical endeavors in 2023 and beyond.

Understanding the Basics of Power Wire Types for Your Electrical Projects

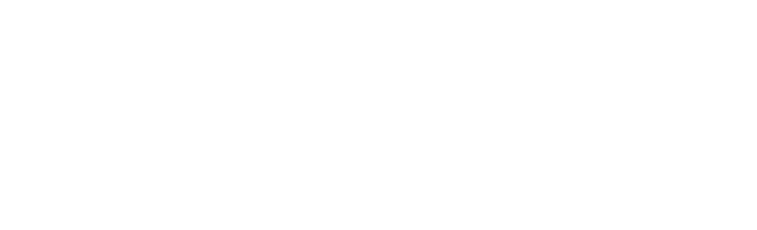

When working on electrical projects, understanding the different types of power wires is crucial for ensuring safety and efficiency. Power wires can vary greatly in their construction and application, which can influence the overall performance of your project. According to the National Electrical Manufacturers Association (NEMA), selecting the right wire can significantly affect not only durability but also the energy efficiency of electrical systems. For instance, using copper wire, which has a higher conductivity than aluminum, can yield up to 25% better performance in terms of energy loss over time.

Furthermore, the Insulated Cable Engineers Association (ICEA) emphasizes the importance of using the correct insulation type for specific environments. For example, in damp or wet conditions, THWN (Thermoplastic Heat and Water-Resistant Nylon-coated) wire is often recommended due to its moisture resistance and durability under extreme conditions. Similarly, high-temperature environments benefit from wires like RTD (Rubber Thermoplastic) which can withstand temperatures up to 90°C without degrading. Understanding these specifications not only aids in compliance with electrical codes but also enhances the longevity and safety of electrical installations.

Key Considerations When Choosing Power Wires for 2023

When selecting power wires for electrical projects in 2023, several key considerations must be kept in mind to ensure safety and efficiency. Firstly, understanding the wire gauge is critical. According to the National Electrical Code (NEC), the gauge determines the amount of current a wire can safely carry. For instance, a 12-gauge wire can handle up to 20 amps, making it a popular choice for residential circuits. Prioritizing the correct gauge for your project will prevent overheating and potential fire hazards.

Moreover, insulation type plays a vital role in wire selection, especially when considering environmental factors. Wires with thermoplastic insulation, such as THHN, are rated for higher temperatures and provide added moisture protection, making them ideal for both indoor and outdoor applications. A report from the Institute of Electrical and Electronics Engineers (IEEE) indicates that improper insulation can lead to significant energy loss, as much as 5-10% in some scenarios. Hence, investing in quality insulation tailored to specific project conditions is essential.

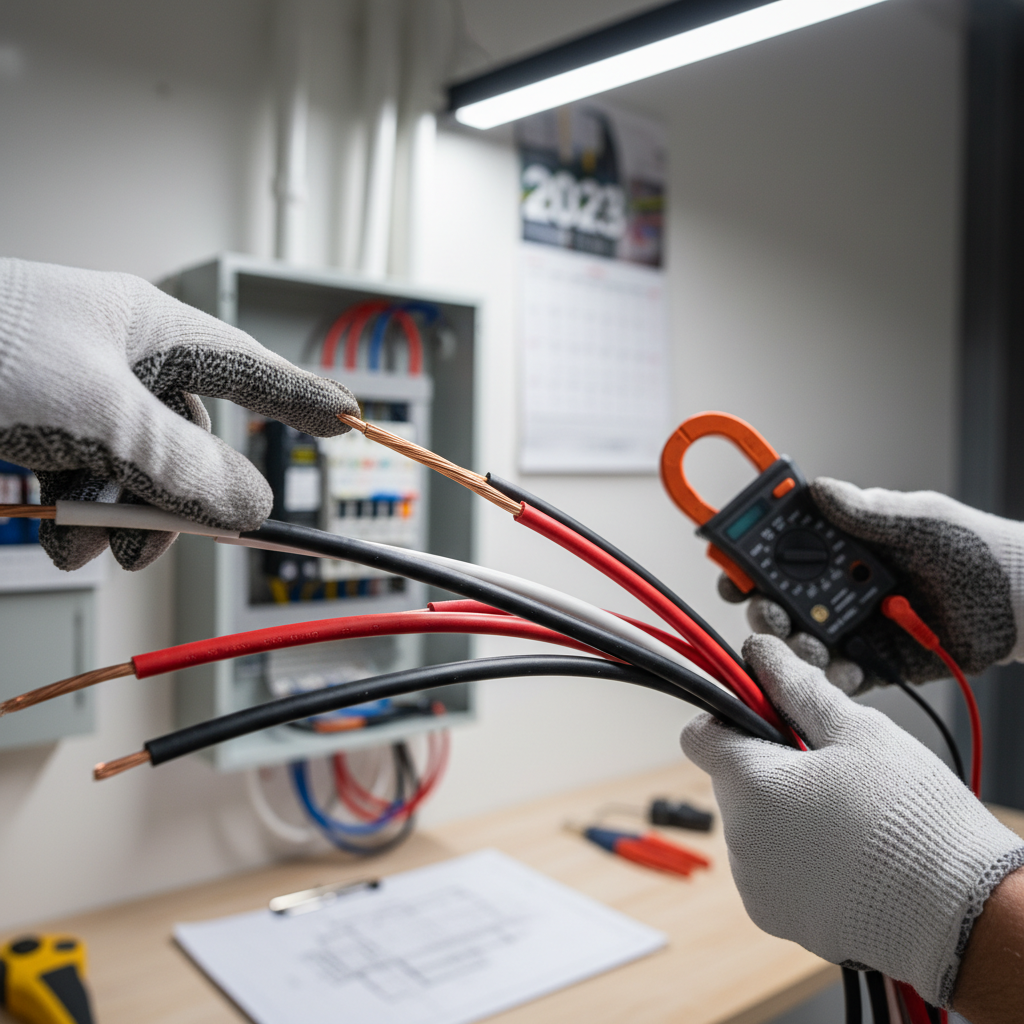

Comparing the Most Common Types of Power Wires: PVC, XLPE, and More

In 2023, the choice of power wire types is crucial for the success of electrical projects. Among the most common types are PVC and XLPE wires, each offering distinct advantages. PVC (Polyvinyl Chloride) cables are widely appreciated for their flexibility and cost-effectiveness, making them suitable for various applications, especially in residential buildings. On the other hand, XLPE (Cross-Linked Polyethylene) cables excel in high-temperature environments and offer superior resistance to chemicals and moisture, providing enhanced durability for industrial projects.

Recent market analyses indicate a growing focus on renewable energy, which is expected to spur demand for quality wiring solutions. According to industry reports, the global wire and cable materials market is projected to grow significantly, driven by increased investments in solar, wind, and hydropower. This growth will emphasize the need for advanced power cables that can support these renewable sources, underscoring the importance of selecting the right wire type for specific applications. With innovations continuing to emerge in this sector, including the introduction of specialized low and medium voltage cables, 2023 presents a pivotal year for electrical infrastructure development.

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

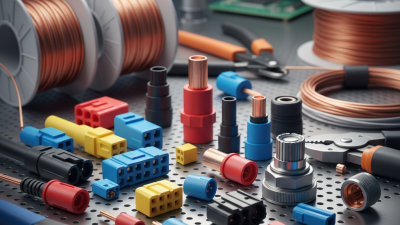

| Wire Type | Material | Insulation Type | Voltage Rating | Temperature Rating | Applications |

|---|---|---|---|---|---|

| PVC Wire | Copper | PVC | 600V | 90°C | Residential wiring |

| XLPE Wire | Aluminum | XLPE | 600V | 90°C | Industrial applications |

| NRG Wire | Copper | Thermoplastic | 600V | 75°C | Low voltage distribution |

| Submersible Pump Cable | Copper | Thermoplastic | 600V | 90°C | Water well pumps |

| MC Cable | Copper | Flexible Metal | 600V | 75°C | Commercial buildings |

| SOOW Cable | Copper | Rubber | 600V | 90°C | Portable equipment |

| THHN Wire | Copper | Nylon | 600V | 90°C | General purpose |

| UF Wire | Copper | Nylon | 600V | 75°C | Underground feeder applications |

| Ethernet Cable | Copper | Twisted Pair | Not applicable | Not applicable | Networking |

| Control Cable | Copper | PVC | 600V | 75°C | Automation systems |

Safety Standards and Regulations for Power Wire Usage in Electrical Work

When working on electrical projects, adhering to safety standards and regulations is crucial for protecting both you and your property. According to the National Fire Protection Association (NFPA), electrical failures were responsible for about 68,000 home structure fires in 2019, highlighting the critical need for proper wire usage and compliance with safety guidelines (NFPA, 2020). Professional electricians are urged to stay updated on local codes, ensuring that the power wires they select meet the necessary specifications for insulation, voltage ratings, and environmental conditions.

Tip: Always reference the National Electrical Code (NEC) for minimal safety standards tailored to your location. Using wires rated for specific applications—such as THHN for general purpose or NM-B for residential wiring—can prevent potential hazards.

Additionally, manufacturers often provide installation guidelines that specify the proper amperage loads and environmental factors to consider, which should never be overlooked. For instance, using a wire gauge that is too low for your intended current can lead to overheating and fires. The American Wire Gauge (AWG) system provides clear specifications for wire sizes and their corresponding capacity; a 12 AWG wire, for example, can safely carry up to 20 amps, making it suitable for standard household circuits.

Tip: When selecting wire types, consider not only the installation environment but also the load requirements, applying the “80% rule” to prevent overheating due to continuous loads.

Top 10 Power Wire Types in 2023

Innovative Trends in Electrical Wiring: What to Expect in 2023

In 2023, the electrical wiring industry is poised to witness transformative changes driven by innovative trends and technological advancements. A significant focus will be on the adoption of smart wire types that enhance efficiency and safety in electrical projects. The increasing integration of sustainable materials and smart technology is expected to shape the future of wiring solutions.

Companies are likely to invest in research and development to create wires that not only support current energy demands but also accommodate the growing influence of renewable energy sources.

As the global digital twin market expands, expected to grow from $15.23 billion in 2023 to $238.88 billion by 2031, industries are leaning toward digitalization in their electrical projects. This trend underscores the importance of advanced wiring solutions that can seamlessly integrate with digital twin technologies. Additionally, the integration of AI and machine learning in project execution is driving efficiency and reducing costs, allowing for more innovative applications of power wire types. The promising compound annual growth rate of 41.70% reflects the impact of these developments, making 2023 a pivotal year for the evolution of electrical wiring in diverse sectors.

Related Posts

-

2025 How to Choose the Best Wire Cable Connectors for Maximum Efficiency

-

2025 Top Cable Harness Innovations and Trends You Need to Know

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation

-

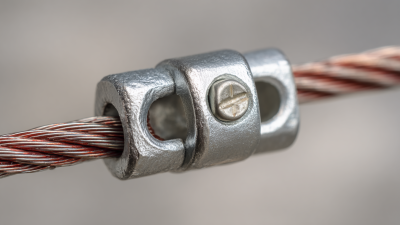

Understanding the Importance of Cable Clamps in Modern Electrical Installations

-

The Ultimate Guide to Understanding Control Wires: Applications, Types, and Best Practices

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners