Top 10 Types of Cable Wire for Your Electrical Projects?

When embarking on electrical projects, selecting the right cable wire is crucial. There is a vast array of cable wire options available today. The choice can often be overwhelming, especially for those new to the field. Each type serves a unique purpose, and understanding these differences can significantly impact project outcomes.

Different projects demand different specifications from cable wire. Whether it’s for residential wiring, outdoor use, or industrial applications, knowing which cable wire to use is essential. Some cables are designed for high voltage, while others work best in low-voltage scenarios. Mistakes in selection may lead to complications later on, creating headaches that could have been avoided.

This article explores the top ten types of cable wire suitable for various electrical projects. It highlights essential characteristics and practical applications for each type. By the end, you will better understand which cable wire fits your needs best. Remember, making informed choices is the key to successful electrical work. Choose wisely!

Overview of Electrical Wiring Types and Their Uses

When considering electrical wiring types, understanding their specific applications is crucial. The National Electrical Manufacturers Association (NEMA) indicates that different wire types serve unique functions. For instance, THHN wire, known for its heat resistance, is commonly used in dry locations. Its versatility makes it ideal for residential and commercial projects alike.

Another type is NM (non-metallic) cable, often seen in residential setups. It’s easy to install and suitable for indoor use. However, NM cable is not water-resistant, which poses challenges in damp areas. Many electricians recommend using other types for outdoor wiring, like UF (underground feeder) cable, which can withstand moisture.

Despite advancements in wiring technology, mistakes can happen. Many projects suffer due to improper wire selection or installation errors. For example, using THHN in wet locations can lead to insulation failure. Reports show that improper installations account for a significant percentage of electrical fires. Thus, careful consideration of wire types is essential to ensure safety and functionality.

Understanding Cable Wire Specifications and Ratings

When working on electrical projects, understanding cable wire specifications is crucial. Different types of cables come with unique features. These features can affect safety and performance. For instance, voltage ratings indicate the maximum voltage the wire can handle. Using a wire rated for less voltage can lead to risks.

The wire gauge is another essential aspect. Thicker wires can carry more current safely. Yet, they are also bulkier and harder to manage. Sometimes, it might be tempting to use a thinner wire for convenience. This can cause overheating.

Insulation types also matter significantly. Some wires have better insulation for outdoor use. Others are better suited for indoor applications. Choosing the right insulation can prevent electrical arcing. This, in turn, protects your home and appliances. It's easy to overlook these details, but doing so may result in costly mistakes. Reflecting on these specifications is vital for successful wiring projects.

Common Types of Cable Wire for Residential Electrical Projects

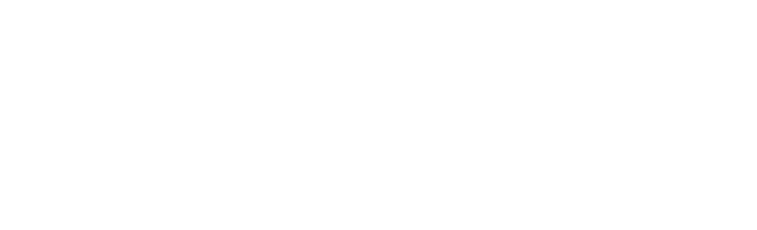

When tackling residential electrical projects, choosing the right cable wire is crucial. There are various types of cable wires to consider, each serving different purposes. For example, NM-B cable is often used for general wiring. It is flexible and ideal for indoor projects. UF cable, on the other hand, is suitable for outdoor use. It can withstand moisture and other outdoor elements.

Another popular type is THHN wire. This wire is often used in commercial applications but can also be utilized in homes. It comes in various colors, making it easy to identify different circuits. However, remember that it requires conduit for protection. Always ensure you are using the right type for your specific needs.

**Tip:** When planning your project, always double-check local codes. They can vary significantly and influence your choices. It's essential to use wires that meet regulations to ensure safety.

It’s easy to overlook the details in a project. Keeping your workspace organized helps avoid mistakes. For instance, mismatched wire types can lead to potential hazards. Take time to label any wires after they are cut. This reduces confusion later on and saves time during installation.

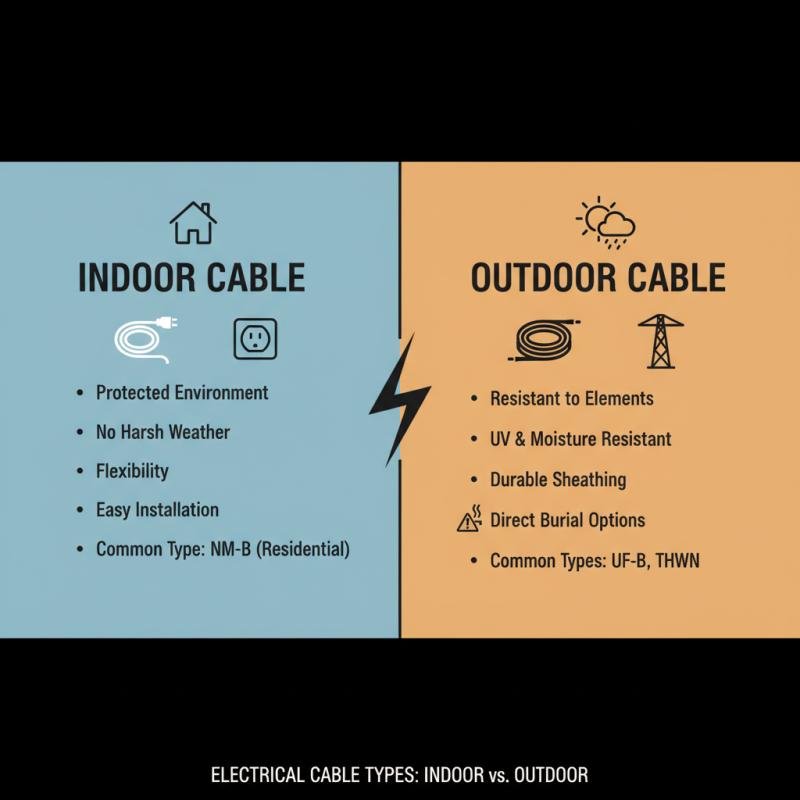

Comparing Indoor vs Outdoor Electrical Cable Wire Types

When considering indoor and outdoor electrical cable wire types, there are key differences to note. Indoor cables are typically designed for protected environments. They are not exposed to harsh weather, so flexibility and ease of installation are often prioritized. For instance, non-metallic sheathed cables, like NM-B, are commonly used in residential applications. They offer reliable performance but are not suitable for outdoor use.

On the other hand, outdoor cables must withstand various elements. These cables are usually weather-resistant and UV-stabilized. One common type is UF (Underground Feeder) cable, designed specifically for direct burial. According to industry reports, outdoor cables need a strong outer jacket, typically made from PVC or polyethylene, to prevent damage. This can be crucial in areas that experience extreme weather conditions, such as heavy rain or snow.

However, many DIY enthusiasts may overlook the significance of these distinctions. Choosing the wrong cable can lead to long-term issues, such as failures and even hazards. Failure rates can increase by 15-20% when indoor wires are used outside, according to studies. Careful selection and awareness of cable specifications are crucial for successful electrical projects.

Best Practices for Choosing the Right Cable Wire for Your Needs

Choosing the right cable wire for your project can be challenging. Many factors can affect your decision. Start by determining the purpose of the wire. Different applications require different types of cable. For instance, wiring for lighting may not be suitable for heavy machinery. Understand the specific needs of your electrical system before making a choice.

Consider the wire's gauge. Thicker wires can carry more current but are harder to work with. Voltage ratings also matter. Using wires rated for lower voltage in high-voltage applications can lead to safety hazards. It’s essential to balance ease of installation with safety requirements. Misjudging these aspects can result in costly mistakes.

Don’t forget to check insulation types. Some environments demand specific insulation to withstand heat or moisture. If you’re unsure, ask for guidance. Reflect on your project scope. Trying to cut costs by choosing inferior materials may seem tempting but could compromise safety. A well-informed decision can save headaches later on.

Top 10 Types of Cable Wire for Your Electrical Projects

| Cable Type | Application | Wire Gauge | Insulation Type | Price per Foot |

|---|---|---|---|---|

| Romex (NM) | Residential wiring | 14, 12, 10 | PVC | $0.30 |

| THHN/THWN | Commercial wiring | 14 - 4 | Nylon, PVC | $0.20 |

| Speaker Wire | Audio connections | 16, 14 | PVC | $0.15 |

| Coaxial Cable | TV and internet | Various | PVC | $0.25 |

| Cat5e/Cat6 | Networking | 22 | PVC | $0.20 |

| SJOOW | Portable equipment | 12, 14 | Rubber | $0.40 |

| UF Cable | Underground wiring | 14 - 6 | PVC | $0.35 |

| MC Cable | Metal conduit applications | 12, 14 | Metal sheath | $0.45 |

| Armored Cable | High-durability applications | 12 - 6 | Steel armor | $0.50 |

| Flat Cable | Tight spaces | Various | PVC | $0.28 |

Related Posts

-

What is cable wire and how is it used in various applications?

-

Top 10 Best Control Wire Types for Optimal Performance and Durability

-

Top 10 Benefits of Using Marine Cable in Modern Industries?

-

How to Choose the Best Cable Solutions for Your Home and Office Needs

-

10 Essential Tips for Choosing the Right Cable Clamp for Your Project

-

10 Essential Tips for Choosing the Right Electrical Cable for Your Needs?