Top 10 Tips for Choosing the Perfect Cable Harness for Your Project

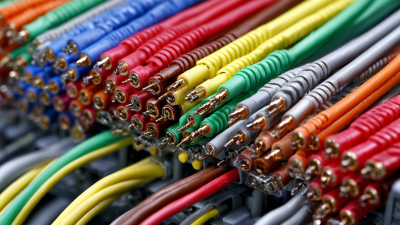

In today’s rapidly evolving technological landscape, the importance of selecting the right cable harness for any project cannot be overstated. A well-designed cable harness can significantly enhance system reliability and performance, which is crucial, especially in industries where precision is paramount, such as automotive, aerospace, and telecommunications. According to a report by MarketsandMarkets, the global market for cable harnesses is projected to reach USD 150 billion by 2024, growing at a CAGR of 7.2%, underscoring the rising demand for these essential components.

Choosing the perfect cable harness is essential not only for project efficiency but also for meeting regulatory standards and ensuring safety. With increasing complexity in electronic systems and a growing focus on miniaturization, the need for high-quality cable harness solutions has never been more critical. Industry experts suggest that nearly 30% of electronic failures stem from poor wiring and connectivity, highlighting the necessity for careful selection and consideration in harness design. This guide presents the top 10 tips for choosing the right cable harness, aimed at helping engineers and project managers navigate the intricacies of harness selection to achieve optimal results.

Understanding the Importance of a Cable Harness in Your Project

A cable harness is a crucial component in various projects, from automotive to aerospace and consumer electronics. It not only organizes and protects wires but also enhances the efficiency and reliability of electrical systems. According to a report by MarketsandMarkets, the global wire harness market is projected to reach $71.3 billion by 2026, growing at a CAGR of 7.5% from 2021. This growth highlights the increasing demand for effective cable management solutions across industries.

Choosing the right cable harness can significantly impact a project's performance and longevity. A well-designed harness minimizes risks such as electrical shorts, interference, and wear that can arise from improperly managed cables. For instance, a study published in the IEEE Transactions on Industry Applications found that poor cable management can lead to a 30% increase in failure rates in electrical systems. By understanding the importance of a cable harness and investing in the right one for their specific needs, project managers can ensure improved safety and operational efficiency, ultimately saving time and costs associated with repairs and replacements.

Identifying Your Project's Specific Cable Harness Requirements

When embarking on a project that requires a cable harness, pinpointing your specific needs is essential. The first step is to assess the operational environment where the harness will be used. Consider factors such as temperature fluctuations, exposure to moisture, and potential mechanical stress. Understanding these conditions will guide you in selecting materials and designs that enhance durability and performance.

Next, evaluate the electrical requirements of your project. Determine the type and gauge of wires needed, as well as the current and voltage specifications. This will help you avoid issues related to overheating or signal loss. Additionally, think about the layout of the harness and how it will interact with other components. Creating a schematic diagram can facilitate better planning and more effective communication with manufacturers, ensuring that the final product aligns perfectly with your project's demands.

Top 10 Tips for Choosing the Perfect Cable Harness for Your Project - Identifying Your Project's Specific Cable Harness Requirements

| Tip Number | Tip Description | Considerations | Common Applications |

|---|---|---|---|

| 1 | Determine the Cable Type Needed | Voltage, current, and environmental factors | Automotive, aerospace |

| 2 | Assess Length Requirements | Measure space in your project | Industrial machinery |

| 3 | Identify Connector Types | Match connectors to devices | Consumer electronics |

| 4 | Evaluate Insulation Material | Temperature and chemical exposure | Medical devices |

| 5 | Consider Cable Harness Dimensioning | Space constraints and layout | Telecommunications |

| 6 | Analyze Environmental Conditions | Humidity, dust, and temperature | Outdoor applications |

| 7 | Plan for Assembly and Routing | Ease of installation and maintenance | Robotics |

| 8 | Check for Compliance Standards | Industry regulations and safety | Electrical devices |

| 9 | Budget for Quality Components | Balance cost and reliability | High-reliability systems |

| 10 | Seek Expert Recommendations | Consult with industry professionals | Custom projects |

Evaluating Cable Materials and Their Performance Characteristics

When choosing a cable harness for your project, evaluating cable materials and their performance characteristics is crucial. Different materials offer varying levels of flexibility, durability, and resistance to environmental factors such as heat and moisture. For instance, polyethylene and PVC are common insulation materials that provide basic protection, but if your project involves extreme conditions, consider using materials like Teflon or silicone, which can withstand higher temperatures and provide superior flexibility.

Tip: Always consider the environment in which the cable harness will operate. If it will be exposed to chemicals or harsh conditions, opt for cables that feature enhanced insulation properties. This can prevent early degradation and ensure longevity in performance.

Additionally, the electrical conductivity of the materials used in the cable harness can significantly influence your project’s efficiency. Copper is often the preferred choice due to its excellent conductivity, but aluminum is a lightweight alternative that can be suitable for specific applications.

Tip: Evaluate the current requirements of your project to select an appropriate conductor size. Ensuring you have the right gauge will prevent overheating and power losses, optimizing the overall performance of your cable harness.

Performance Characteristics of Different Cable Materials

Assessing Connector Types and Their Compatibility

When choosing the perfect cable harness for your project, understanding connector types and their compatibility is crucial. The right connectors can enhance the efficiency and reliability of your system. For instance, when dealing with medical applications, as seen in recent studies on vascular anastomosis connectors, the selection of materials such as polylactic acid and polycarbonate can significantly impact performance due to their distinct biomedical properties. This consideration highlights the importance of assessing not just the mechanical fit, but also the compatibility of materials used in connectors.

Furthermore, new regulations, such as the NEC 2020, emphasize the need for uniformity in connector types across components. To ensure smooth integration, it's advisable to select connectors that match both in type and brand with those already in your system. Additionally, when choosing connectors, consider their sterile properties if your project involves sensitive applications. Evaluating factors such as environmental conditions and compatibility with various devices will help guarantee that your cable harness operates effectively in its intended environment. Always keep current industry standards in mind to avoid potential issues down the line.

Ensuring Proper Cable Harness Testing and Quality Assurance Processes

When selecting a cable harness for your project, ensuring rigorous testing and quality assurance processes is paramount.

According to a report by IPC, 35% of electronic failures in the field are linked to poorly assembled cable harnesses, highlighting the importance of thorough testing protocols. Implementing standardized testing methods such as thermal cycling and vibration testing can significantly enhance the reliability of the harness, ensuring that it meets the specific requirements of various environmental conditions.

Quality assurance should also involve careful material selection and inspections at multiple stages of production. Industry standards, such as those established by the International Electrotechnical Commission (IEC), provide guidelines for assessing the quality of materials used in cable harnesses. Data from a recent study indicates that harnesses manufactured with high-quality materials have a 50% lower failure rate in critical applications.

Incorporating these testing and quality assurance measures not only safeguards your project from potential failures but also optimizes performance and longevity in demanding applications.

Related Posts

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

2025 Top Cable Harness Innovations and Trends You Need to Know

-

Top 10 Must-Know Facts About Cable Harnesses for Your Next Project

-

What is a Wire Cable Connector? Understanding Types and Applications

-

Understanding the Role of Wire Cable Connectors in Modern Technology Systems

-

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023