How to Master Wire Harness Assembly for Your Projects?

Wire harness assembly is a critical component in various industries, including automotive, aerospace, and electronics. According to a report by MarketsandMarkets, the wire harness market is expected to reach $89.54 billion by 2026, growing at a CAGR of 4.5% from 2021. This growth reflects the increasing demand for complex wiring systems across different applications. Wire harnesses facilitate electrical connections, enhancing efficiency and safety.

Mastering wire harness assembly requires a keen understanding of the components involved. Designers must account for factors like wire gauge, insulation types, and connector styles. Each detail can impact performance and longevity. It's important to remember that even small mistakes in assembly can lead to significant failures. For instance, incorrect crimping can result in poor electrical contacts, creating risks in high-stakes environments.

Incorporating best practices into your assembly process is essential. Attention to detail is crucial, as overlooking minor aspects can lead to major drawbacks. Continuous learning and adapting to emerging technologies can ensure better practices in wire harness assembly. Reflecting on past projects can help identify areas for improvement, paving the way for future success in this intricate field.

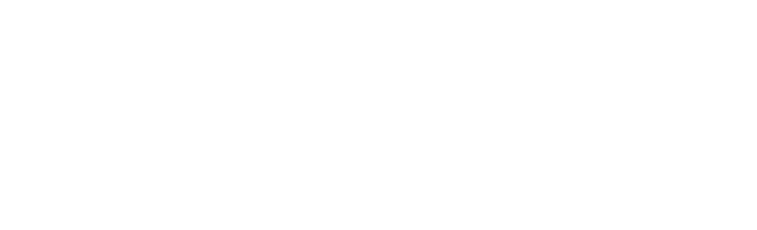

Understanding the Importance of Wire Harness Assembly in Projects

Wire harness assembly is crucial for the efficiency of electrical systems. According to a recent industry report, over 70% of equipment failures are linked to poor wiring connections. This emphasizes the importance of mastering wire harness assembly. Proper assembly can enhance reliability and reduce downtime in projects, making it an essential skill for engineers and technicians.

Tips for mastering wire harness assembly include paying close attention to wire types and lengths. Selecting the appropriate gauge wire matters significantly. For instance, using too thin wire can lead to overheating. Additionally, ensure that connections are secured properly. Loose connections can lead to faults, which may cause project delays.

Focus on organization during assembly. Using color-coded wires can simplify the process. Many projects fail due to tangled wires or incorrect connections. Establishing a systematic approach can enhance your efficiency. Reflect on your assembly process regularly and identify areas for improvement. A well-organized workspace can lead to better outcomes.

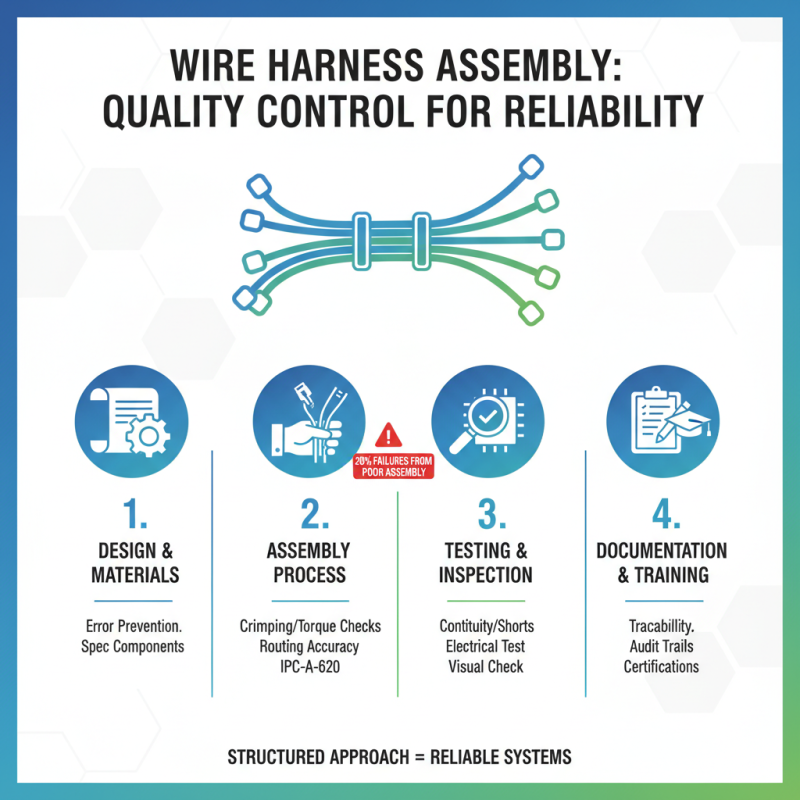

Essential Tools and Materials for Wire Harness Assembly

When diving into wire harness assembly, having the right tools and materials is crucial. You will need wire cutters, crimping tools, and heat shrink tubing. These essentials allow for precise cuts and strong connections. A well-organized workspace makes the process smoother. Consider separate bins for wires and connectors to avoid mix-ups.

Tips: Always double-check your connections. A small mistake can lead to failures down the line. Take your time during assembly. Rushing often results in overlooked details.

Selecting the appropriate wire gauge is important too. Thicker wires handle more current, while thinner ones are easier to manipulate. Testing your assembly before finalizing it is a smart move. You might find unexpected flaws. Reflecting on your mistakes is part of the learning curve, helping you improve over time. Embrace the challenges, and remember that even small adjustments can lead to significant improvements.

Step-by-Step Guide to Designing a Wire Harness

Designing a wire harness requires careful planning and attention to detail. Begin with a clear understanding of your project's specifications. Choose the right materials based on the expected environmental conditions. Reports indicate that nearly 30% of failures in electrical systems stem from poor wire harness design. This underscores the importance of precision during the design phase.

Next, sketch the layout of the wire harness. Diagramming helps visualize connections and potential challenges. Material selection plays a pivotal role. Data shows that using high-quality insulation can extend the lifespan of your harness by over 40%. Don’t rush through component placement; improper spacing can cause short circuits or signal interference. Are your connectors easily accessible for future servicing? Design with maintenance in mind.

After drafting, conduct a thorough review. Engage your team in discussions about potential pitfalls. Feedback is crucial. Industry surveys reveal that 25% of projects miss deadlines due to overlooked details in wire harness assembly. Analyze past experiences; what went wrong? Reflection can lead to significant improvements. Keep refining your approach for better outcomes.

Techniques for Efficient Wire Termination and Connection

Mastering wire termination and connection is crucial for any project involving wire harness assembly. Quality connections ensure longevity and minimize failures.

According to a recent industry report, 30% of electrical device failures are linked to poor wire connections. This statistic underscores the importance of mastering efficient techniques.

Effective wire termination requires careful attention to detail. Stripping wire incorrectly or using improper tools can lead to inadequate connections. A study found that only 70% of technicians use the appropriate tools for termination. This negligence can be detrimental. Using the right crimping tool can reduce failure rates by up to 50%.

It’s essential to consider environmental factors. Moisture, for example, can increase the likelihood of corrosion. The report indicates that 25% of issues arise from environmental damage.

Technicians should use proper sealing methods to protect connections. Investing time in these details pays off in reliability and performance.

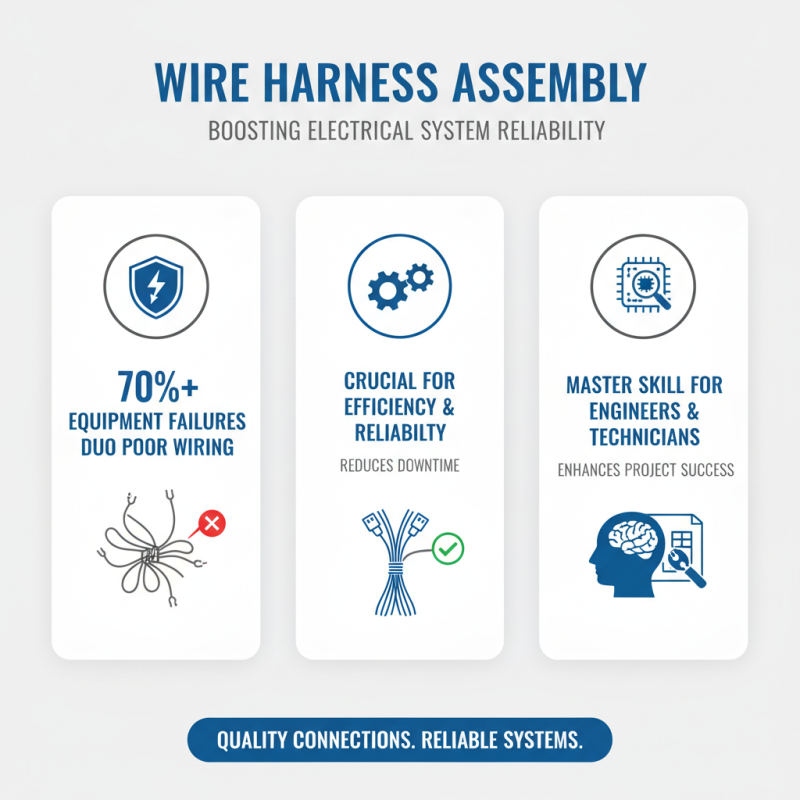

Quality Control Measures in Wire Harness Assembly Process

Quality control measures in wire harness assembly are crucial for ensuring reliability in electrical systems. Organizations should adopt a structured approach. Data from industry reports indicate that nearly 20% of wiring failures stem from poor assembly practices. This emphasizes the need for stringent quality checks throughout the assembly process.

Implementing effective inspection methods can significantly reduce errors. Visual inspections, for example, can catch misalignments or loose connections early on. In a survey, 70% of assembly professionals reported that enhanced training improved their quality assurance efforts. Investing in training programs is key. However, some teams still overlook the importance of detailed documentation. This can lead to recurring issues that impact project timelines.

Integrating automated testing equipment can reveal hidden issues. Yet, many facilities hesitated to adopt such technologies due to costs. As a result, they miss out on identifying faults quickly. Quality control is not just a phase; it’s a continuous practice needing constant reflection and adaptation. The journey towards mastering wire harness assembly involves recognizing and addressing these gaps for optimal performance.

Related Posts

-

Ultimate Guide to Wire Harness Top Tips for Installation and Maintenance

-

2025 Top Cable Harness Innovations and Trends You Need to Know

-

What is cable wire and how is it used in various applications?

-

Best Electrical Wire Types for Your Projects?

-

Understanding the Role of Wire Cable Connectors in Modern Technology Systems

-

Top 10 Tips for Choosing the Perfect Cable Harness for Your Project