Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

In today's world, where technological advancements are the norm, understanding the essential components of various systems has become crucial. One such critical element is the cable harness, a collection of wires or cables that transmit electrical signals and power throughout devices. As the backbone of many electronic setups, cable harnesses ensure that systems function efficiently and reliably. For beginners delving into the realm of electrical engineering and electronics, having a well-rounded understanding of cable harnesses is paramount.

This comprehensive guide aims to equip novices with the fundamental knowledge about cable harnesses, providing insights into their design, function, and applications. We will explore the intricacies of cable harness construction and the various materials used, as well as unveil the top 10 considerations when selecting or working with cable harnesses. By breaking down these essential aspects, we hope to clarify the complexities surrounding this vital component, making it easier for beginners to appreciate the importance of cable harnesses in modern technology.

Key Components of Cable Harness: Identifying Essential Parts for Beginners

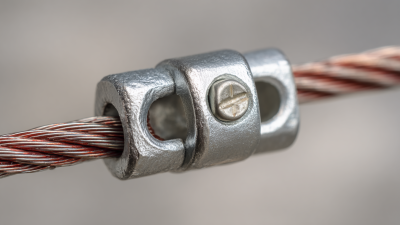

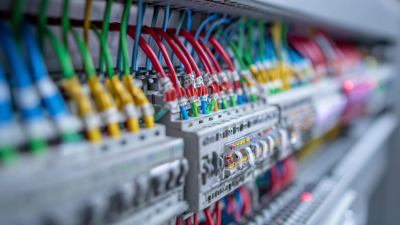

Cable harnesses are intricate assemblies of wires and cables that transmit electrical power and signals within various devices. For beginners, it’s essential to understand the key components that make up a typical cable harness. At the core of these assemblies are wires, which are responsible for carrying electrical current. The gauge of wires can significantly affect their performance, and thus, selecting the right diameter is crucial to ensure efficiency and safety.

In addition to wires, connectors play a vital role in cable harnesses. They facilitate secure connections between different components, enabling seamless communication and power transfer. There are several types of connectors, including bullet connectors, spade connectors, and multi-pin connectors, each serving specific purposes depending on the application. Lastly, protective coverings such as heat shrink tubing or conduit are essential for safeguarding the wires from physical damage and environmental factors. Understanding these components helps beginners appreciate the functionality and importance of cable harnesses in electrical systems.

Types of Cable Harnesses: Understanding Different Designs and Their Uses

Cable harnesses are essential components in a variety of industries, including automotive, aerospace, and consumer electronics. Understanding the different designs available can help in selecting the right type for specific applications. Broadly, cable harnesses can be categorized into three main types: round, flat, and custom harnesses. Round harnesses are ideal for applications requiring flexibility and strength, often favored in automotive and machinery sectors. According to a recent report by Market Research Future, the global market for automotive wire harnesses is projected to reach USD 70 billion by 2025, reflecting the critical role of these components in modern vehicle design.

Flat cable harnesses, on the other hand, are beneficial for applications where space is a prime concern, such as in consumer electronics. Their design allows for easier routing in tight spaces. Furthermore, custom harnesses can be tailored to meet unique requirements, which is increasingly important in specialized fields like medical devices and renewable energy solutions. A study published by Grand View Research indicates that the custom cable assembly market is expected to witness substantial growth, achieving a valuation exceeding USD 25 billion by 2027. This underscores the trend toward more specialized applications and the ongoing innovation in cable harness design to meet emerging industry needs.

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

| Cable Harness Type | Design Characteristics | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Round Cable Harness | Flexible design with round cross-section | Industrial machinery, automotive | Highly flexible, easy to install | Limited space efficiency |

| Flat Cable Harness | Flat profile, compact layout | Consumer electronics, computers | Space-saving, lightweight | Less robust against physical stress |

| Custom Cable Harness | Tailored to specific requirements | Specialized equipment, military | Optimally designed for functionality | Higher cost and longer production time |

| Sub-Assembly Cable Harness | Pre-assembled components for ease | Automotive, aerospace | Easier installation, reduces assembly time | Requires precise manufacturing |

Manufacturing Process: How Cable Harnesses are Assembled and Tested

The manufacturing process of cable harnesses involves a complex interplay of engineering and assembly techniques. While some manufacturers employ advanced automation, many still rely heavily on manual labor, especially in sectors like automotive and aerospace. This manual assembly process is often surprisingly intricate, necessitating specialized skills and tools to ensure precision and reliability. As industries push for greater efficiency, innovations such as robot-assisted assembly are gaining traction, particularly in aerospace applications where accuracy is paramount.

Recent developments in manufacturing technology are also transforming how cable harnesses are produced. Digital twin technology, for instance, enables manufacturers to simulate and manage the entire wiring process, improving oversight and control. This approach can streamline workflows and enhance productivity while maintaining high standards of quality. Moreover, as companies expand their production capacities, such as in the automotive sector, they are exploring the integration of automated systems to offset the labor-intensive nature of traditional cable harness assembly, illustrating a clear trend towards modernization in this essential manufacturing area.

Common Applications: Where and Why Cable Harnesses are Used

Cable harnesses play a crucial role in various industries, serving as the backbone for electrical systems in applications ranging from automotive to renewable energy. In the global railway sector, for instance, the wiring harness market is projected to expand significantly, indicating the critical need for reliable connections in transport systems. This growth is reflected in the increasing investments in technology and engineering to ensure safety and efficiency in cable assembly solutions.

Tips: When considering cable harness applications, it's essential to ensure that the materials used are durable and suitable for the specific environment. For instance, in new energy fields, silicone rubber has proven beneficial due to its resilience against extreme temperatures and environmental factors.

Moreover, the proliferation of electric vehicles (NEVs) and renewable energy solutions such as solar power highlights the versatile applications of cable harnesses. Understanding the specific requirements of each application can lead to improved performance and longevity. For manufacturers and engineers, integrating advanced materials and innovative designs is vital to keep up with the evolving market demands and ensure optimal functionality.

Maintenance Tips: Ensuring Longevity and Performance of Cable Harnesses

Maintaining cable harnesses is crucial for ensuring their longevity and performance in various applications. Regular inspections are essential; every few months, visually check for signs of wear, fraying, or corrosion. Pay special attention to connectors, as they can accumulate dirt and moisture that may lead to connectivity issues. If any damage is detected, addressing it promptly can prevent more extensive repairs or system failures down the line.

Another key aspect of cable harness maintenance is proper storage and handling. When not in use, store cable harnesses in a cool, dry environment, away from direct sunlight and extreme temperatures. It's also important to avoid bending or twisting the cables excessively, as this can compromise their integrity. Using appropriate cable management tools—such as ties or clips—can keep cables organized and minimize movement that may cause wear over time. By adhering to these maintenance tips, you can significantly extend the operational lifespan of your cable harnesses, ensuring they perform reliably whenever needed.