How to Choose the Right Wire Clamp for Your Projects: A Complete Guide

When embarking on a new project, the choice of hardware can significantly impact both the quality and efficiency of the final outcome. Among the various components available, the wire clamp stands out as an essential tool that facilitates secure electrical connections and provides stability in a multitude of applications. According to John Smith, a leading expert in wiring solutions, "Choosing the right wire clamp is crucial; it can mean the difference between a reliable connection and a potential failure." This statement underscores the importance of understanding the different types of wire clamps and their specific uses.

A wire clamp can come in various materials, sizes, and designs, each tailored for particular environments and requirements. For instance, selecting the appropriate wire clamp can help prevent damage to wiring due to excess vibration, moisture, or thermal expansion. Understanding these factors will not only enhance the durability of your project but also ensure safety and functionality. Whether you’re a DIY enthusiast or a professional contractor, this guide aims to equip you with the knowledge needed to choose the right wire clamp for your specific needs, ultimately setting a foundation for successful project execution.

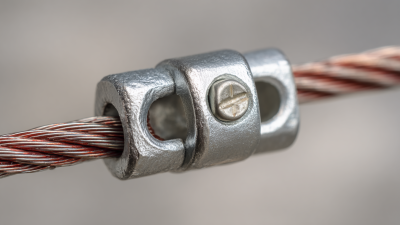

Understanding the Different Types of Wire Clamps Available

When selecting wire clamps for your projects, it's essential to understand the various types available, as each one serves a unique purpose. Wire clamps can be broadly categorized into different styles, including screw clamps, spring clamps, and zip ties, each offering distinct advantages based on the application.

Screw clamps excel in providing a secure, adjustable grip, making them ideal for harsher environments where durability is key. Spring clamps, on the other hand, allow for quick releases and easy handling, suitable for temporary setups. Zip ties, though sometimes overlooked, are excellent for organizing wires and can be used effectively for lightweight tasks.

Additionally, knowing the materials used in wire clamps can influence your decision. For instance, stainless steel clamps are resistant to corrosion, making them perfect for outdoor projects or in humid conditions, whereas plastic clamps might be more appropriate for indoor use, being lightweight and cost-effective. It's important to assess the specific requirements of your project—such as load-bearing capacity, environmental exposure, and ease of use—to make the right choice that ensures safety and reliability. By comparing the features of each type, you can confidently select the best wire clamp to suit your needs.

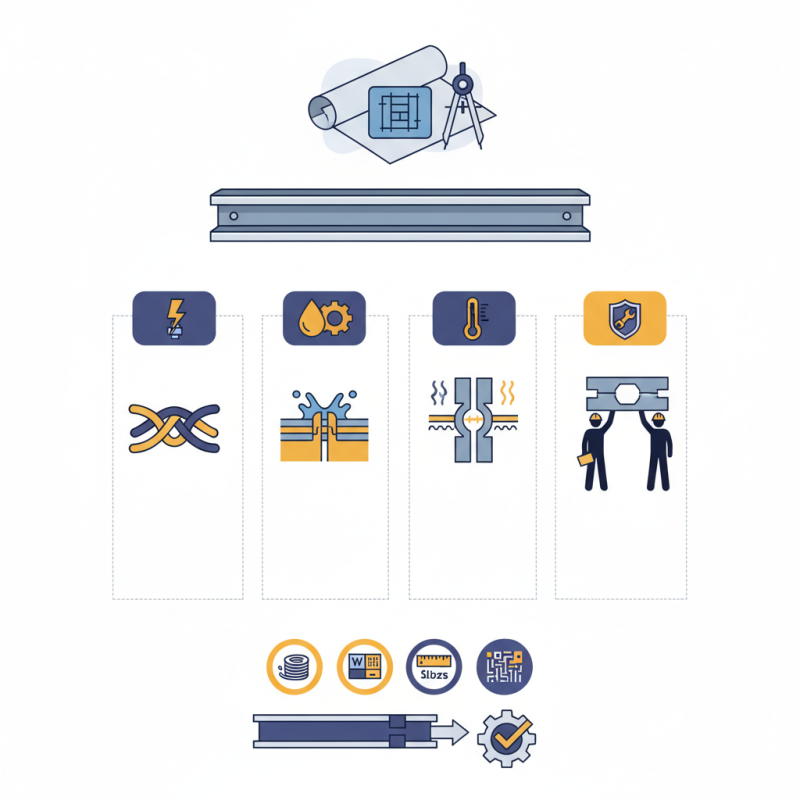

Factors to Consider When Selecting Wire Clamps for Your Project

When selecting wire clamps for your projects, several key factors come into play that can significantly impact the effectiveness and durability of your setup. First and foremost, consider the type of material you'll be working with; for instance, a variety of wire materials, such as copper or aluminum, may require clamps that provide an optimal grip without causing damage. According to a report by the International Wire and Cable Journal, improper clamp selection can lead to a 15% increase in maintenance costs due to frequent replacements or malfunctions.

Another crucial factor is the strength of the clamp. Ensure that the chosen wire clamp can handle the load it will be subjected to without slipping or breaking. Data from the Industrial Fasteners Institute suggests that wire clamps should ideally exceed the maximum anticipated load by at least 20% to ensure reliability.

Tips: Always check the specifications of your clamps, including size and load ratings, to match them accurately with your project requirements. Additionally, consider the environmental conditions where the clamps will be used; for outdoor projects, corrosion-resistant materials may be necessary to enhance longevity. Ensuring that you have the right clamps from the start can save you time and costs in the long run.

Material Choices for Wire Clamps and Their Impact on Performance

When selecting wire clamps for your projects, the material used plays a crucial role in determining performance and durability. Common materials include stainless steel, plastic, and aluminum, each offering distinct advantages.

Stainless steel is renowned for its corrosion resistance and strength, making it ideal for outdoor or industrial applications where exposure to moisture is a concern. Reports indicate that stainless steel clamps can last up to three times longer than their plastic counterparts in harsh environments, making them a preferred choice for demanding tasks.

Plastic wire clamps, on the other hand, are lightweight and resistant to certain chemicals, offering an economical option for less demanding applications. While they may not match the long-term durability of metal clamps, they can perform effectively in indoor settings or low-stress environments.

Industry data suggests that using the appropriate material not only impacts the lifespan of the clamps but also influences the reliability and safety of the connections made in plumbing and automotive projects. Aluminum clamps, while less common, provide a balance between weight and strength, making them suitable for specific situations where minimizing weight is critical, such as in racing applications or quick-connect scenarios.

Installation Tips for Ensuring Secure Wire Clamp Usage

When it comes to installing wire clamps, proper technique is essential for ensuring durability and safety. One crucial tip is to choose the right size of the clamp according to the wire gauge. A clamp that is too loose can lead to slippage, while one that is too tight can damage the wire insulation. Always measure your wire diameter and select a clamp that accommodates it snugly.

Another installation tip is to use appropriate tools to secure the clamps effectively. A torque wrench can help achieve the correct tightness without over-torquing, which can stress the wire. Additionally, consider using rubber grommets or insulating pads between the wire and the clamp to provide extra protection against abrasion and to reduce vibrations, which can cause wear over time.

Lastly, ensure that the mounting surface is clean and free from debris before attaching the clamps. A solid and stable surface will provide better support, minimizing movement that could lead to loosening over time. Periodically check the clamps to confirm they remain tightly fastened, especially in environments subjected to frequent motion or temperature changes.

Wire Clamp Selection Overview

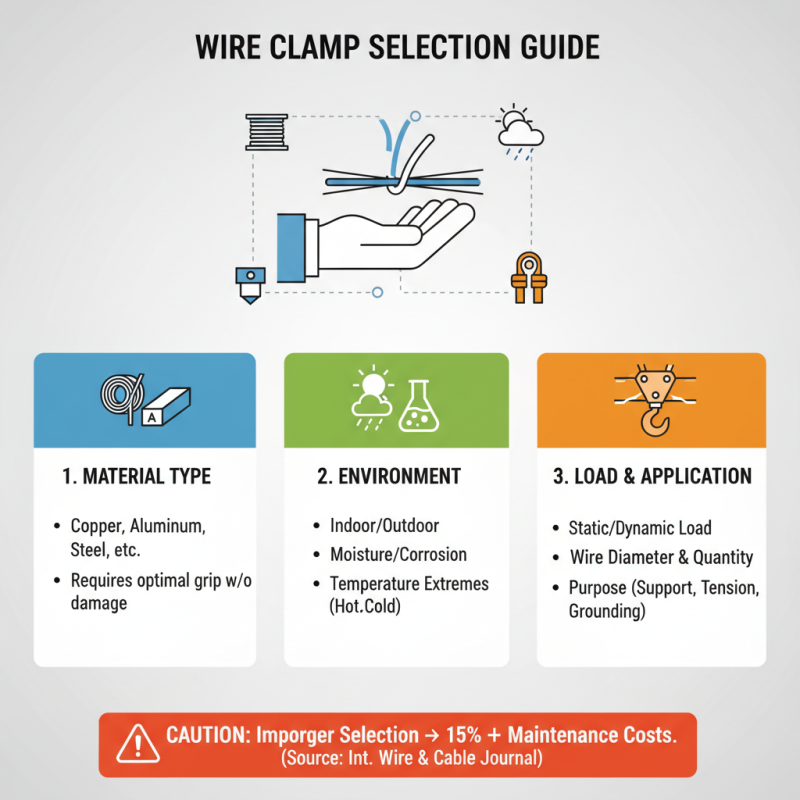

Common Applications of Wire Clamps in Various Industries

Wire clamps play a crucial role in various industries by ensuring secure connections and organization of wires, cables, and hoses. In the automotive sector, for instance, wire clamps are essential for managing wiring harnesses, which are vital for the electrical systems of vehicles. Properly secured wires help maintain safety and functionality, preventing failures that could lead to accidents or malfunctions. Additionally, in the electronics industry, wire clamps are commonly used to tidy up and secure connections within devices, thereby enhancing both performance and longevity.

Another significant application of wire clamps is found in construction and manufacturing settings. Here, they are employed to bundle electrical cables and piping systems, ensuring that these components remain organized and free from damage. The usage of clamps not only improves the aesthetics of the installation but also reduces the risk of wear and tear caused by movement or environmental factors. Furthermore, in the telecommunications industry, wire clamps are utilized to ensure that the extensive networks of cables are both safe and efficient, minimizing disruptions in service caused by cable tangling or disconnections.

Related Posts

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation

-

Top 10 Best Control Wire Types for Optimal Performance and Durability

-

Top 10 Tips for Choosing the Perfect Cable Harness for Your Project

-

Understanding the Importance of Cable Clamps in Modern Electrical Installations

-

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

-

What is a Wire Cable Connector? Understanding Types and Applications