Best Wire Pulling Rope for Your Needs?

Choosing the right wire pulling rope can make a big difference in your projects. A suitable wire pulling rope enhances efficiency and ensures safety. Whether you're an electrician, a DIY enthusiast, or a professional contractor, selecting the right type is essential.

Different projects require different types of wire pulling ropes. Some ropes are lightweight and flexible, making them easy to handle. Others are designed for heavy-duty use, offering strength and durability. It's crucial to think about the specific needs of your tasks. Are you pulling wires through tight spaces? Or do you need to handle heavier loads?

Even though there are excellent options available, each has its limitations. The best wire pulling rope for one project might not work for another. Reflecting on past experiences can provide insight into what works. Make sure to consider factors such as length, material, and tensile strength when making your choice. Your success depends on it.

Understanding Wire Pulling Ropes and Their Importance

Understanding wire pulling ropes is essential for various applications. These ropes are designed to assist in the installation of cables and wires. Their primary function is to provide a reliable means to pull wires through conduits. This process is crucial for electrical installations in homes and buildings.

The importance of wire pulling ropes cannot be overstated. They minimize damage to wires and ensure a smoother installation process. A good quality rope reduces friction and enhances efficiency. However, selecting the right rope requires careful consideration. The thickness, material, and strength must align with your project needs.

Many people overlook these factors, leading to problems. For instance, using a rope that is too thin can result in breakage. On the other hand, a rope that is too thick may not fit in tight spaces. Thus, understanding your requirements is key. The right wire pulling rope should offer both durability and flexibility, ensuring a successful installation.

Best Wire Pulling Rope for Your Needs?

| Rope Type | Material | Diameter (inches) | Weight Capacity (lbs) | Length (feet) | Flexibility |

|---|---|---|---|---|---|

| Synthetic Rope | Nylon | 0.5 | 400 | 100 | High |

| Polyester Rope | Polyester | 0.75 | 600 | 150 | Moderate |

| Steel Wire Rope | Steel | 0.25 | 1000 | 200 | Low |

| Manila Rope | Natural Fiber | 1.0 | 300 | 50 | High |

Factors to Consider When Choosing the Right Wire Pulling Rope

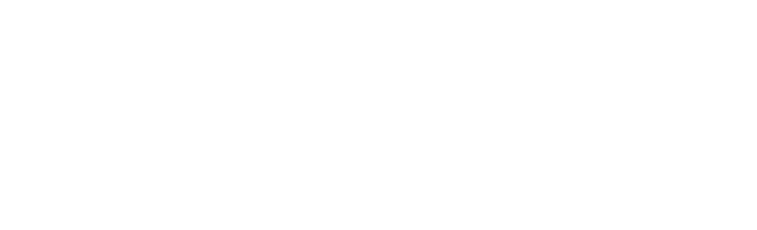

Choosing the right wire pulling rope can be daunting. Several factors come into play. One key aspect is the rope's material. Synthetic fibers are lightweight and durable. Natural fibers can wear out faster but might be more flexible. Consider the environment too. Wet areas need moisture-resistant rope. Dry conditions may allow for lighter options.

Another critical factor is the rope's diameter. Thicker ropes can handle heavier loads, yet they are bulkier. Think about the space where you will use the rope. Narrow passages require thinner ropes. Moreover, the length is equally important. Will you need extended reach? A longer rope might seem convenient but can be harder to manage.

Look into the breaking strength as well. It needs to match or exceed the weight of what you're pulling. A rope with too low a rating can snap under pressure, leading to dangerous situations. Reflect on your specific needs. Will you use the rope often? If so, investing in higher quality could save you in the long run. Making the right choice involves careful thought and a bit of trial and error.

Types of Wire Pulling Ropes and Their Applications

When selecting a wire pulling rope, understanding the types available is crucial. Common options include nylon, polyester, and braided ropes. Nylon ropes are known for their excellent strength and elasticity, making them ideal for heavy-duty applications. Polyester ropes, on the other hand, are less stretchy and offer better UV resistance, which is useful for outdoor tasks.

For light-duty tasks, consider using ropes made from polypropylene. These ropes are lightweight and resistant to water. They may not be as strong as nylon or polyester but are easier to handle. In contrast, some applications require specialized ropes, such as steel wire ropes, which are great for extreme situations demanding high tensile strength.

Tips: Always evaluate your needs before purchasing. For instance, assess the load weight and distance to pull. Ropes should match the specific work conditions. Improper rope selection can lead to ineffective pulling or accidents.

Taking the time to study ropes can prevent future issues. Knowing the limitations and characteristics of each type is vital. Many users overlook the importance of quality, focusing instead on cost. This can lead to problems in high-load scenarios. Awareness of materials and strengths can guide better purchasing decisions.

Best Wire Pulling Ropes: Applications and Specifications

This chart represents the weight capacity of different types of wire pulling ropes commonly used in various applications. Understanding the capacities of these ropes helps to choose the right one for your specific needs.

Tips for Maintaining and Storing Your Wire Pulling Rope

Maintaining your wire pulling rope is crucial for its longevity and performance. Regular inspections can reveal wear and tear that may not be initially noticeable. According to industry studies, about 30% of rope failures are due to improper care and storage. Keeping your rope clean is essential. Dirt and grime can degrade the materials, leading to reduced strength. Simple cleaning techniques, such as rinsing with water, can help maintain its integrity.

Storage also plays a significant role in preserving your rope. Storing it in direct sunlight can cause UV damage, compromising its lifespan. Experts recommend a cool, dry place to prevent mildew and deterioration. A study highlighted that ropes stored in recommended environments last up to 50% longer. Using a dedicated storage bag or reel can prevent tangles and kinks, which could weaken the rope.

Consider the conditions in which the rope is used. High humidity or extreme temperatures can affect performance. Some might neglect these factors, leading to unexpected failures during crucial tasks. It's worth reflecting on the rope's condition before starting major projects. Small steps in maintenance and storage can save significant time and costs in the long run.

Safety Precautions When Using Wire Pulling Ropes

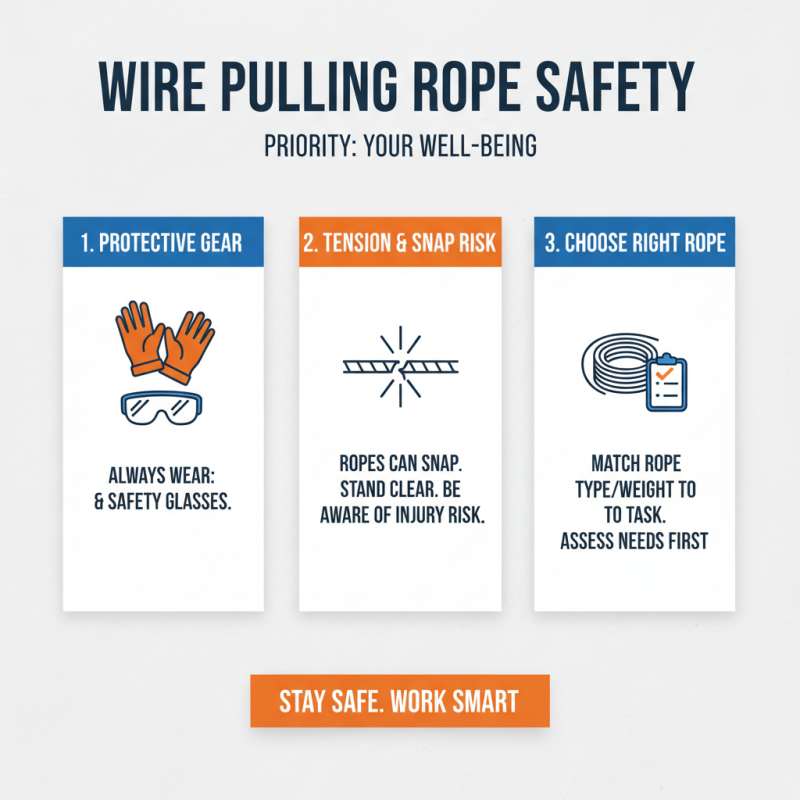

When using wire pulling ropes, safety should be the top priority. Always wear protective gear, including gloves and safety glasses. The ropes can snap under high tension, posing a risk of injury. Choosing the right rope is crucial. Different tasks may require specific types or weights of rope. Make sure to assess your needs before starting.

Check for wear and tear on the ropes regularly. Inspect for frays, cuts, or weak spots. This small step can prevent serious accidents. Furthermore, be mindful of your working environment. Keep the area clear of obstacles to avoid tripping or snagging the rope. Communication with team members is essential. Establish clear signals or lines of communication when pulling.

Improper technique can lead to mishaps. Avoid jerky movements while pulling. Instead, maintain a steady and controlled approach. Sometimes, it helps to have extra hands on deck. Yet, not all teams work well together. Address any misunderstandings or miscommunications before the task starts. This way, everyone is on the same page, enhancing overall safety during the operation.

Related Posts

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

How to Choose the Right Wire Clamp for Your Projects: A Complete Guide

-

10 Essential Tips for Choosing the Right Electrical Cable for Your Needs?

-

Why Is High Voltage Cable Critical for Modern Power Systems?

-

What are the Best Types of Wire Cables for 2026?